Командование материально-технического обеспечения ВВС США (AFMC) намерено использовать технологию 3D-печати для изготовления деталей самолетов.

Благодаря технологиям трехмёрной печати деталей процесс технического обслуживания иремонта самолётов, пооценкам американских военных, станет значительно проще. Вместо заказа идлительного ожидания запасных частей их планируется печатать наавиабазе Тинкер вгороде Оклахома-Сити (США).

Используя компьютерное моделирование, разработчики смогут придумывать теили иные доработки для узлов иагрегатов. Модернизированную деталь можно будет напечатать ипроверить непосредственно насамолёте.

Кроме того, военные рассчитывает спомощью 3D-принтеров оперативно изготавливать различные современные электронные устройства, разработкой ивнедрением которых занимается 76-я группа технического ипрограммного сопровождения ВВС США.

Источник: Популярная механика

Первоисточник: Defense-aerospace

OC-ALC experts foresee 3-D printing, also called additive manufacturing, filling needs ranging from making aircraft engine parts to printing electronic components designed by the 76th Software Maintenance Group.

“We’ve realized that additive manufacturing is a technology that is mature enough, that it is being adopted very strongly in industry right now, and that we as a depot need to build this capability,” said Dr. Kristian Olivero, the complex’s top scientist and engineer.

“This is a step-change technology that will really change in some ways how we can do depot maintenance,” Olivero continued. “It will give us a lot of speed and flexibility, but it’s something that we have to learn to manage and understand how to use.”

The OC-ALC’s plan stems from the additive manufacturing goals in the Air Force’s “Complex of the Future” strategic forecast for the coming decades. Similar complex-specific initiatives are underway at the air logistics complexes at Robins Air Force Base, Georgia, and Hill AFB, Utah.

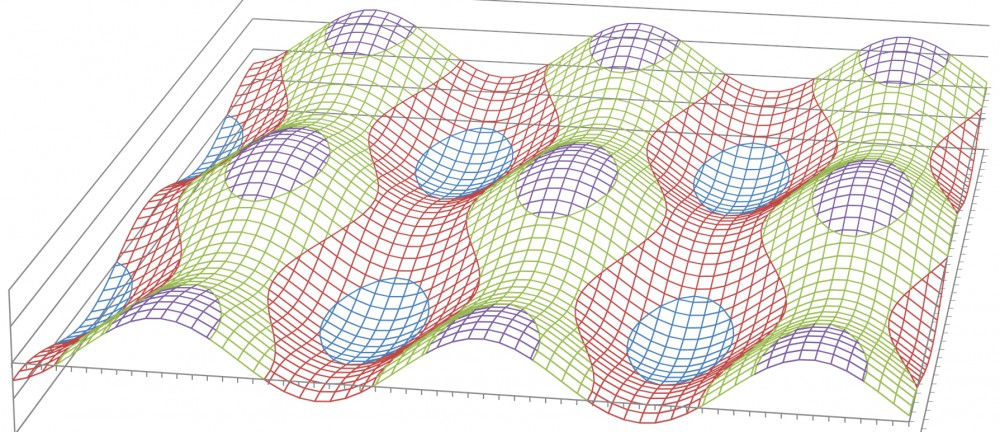

Additive manufacturing machines build objects from raw materials fed into them. Plastic filament that looks like thick fishing line, for example, can be fed into a 3-D printer to construct an object layer by layer on a platform. A growing list of other raw materials includes metal pellets, ceramics and gypsum.

Olivero, the complex’s technical director, said the potential impact of additive manufacturing on depot operations is significant. Replacement engine parts, for example, that are currently bought, shipped to the depot, stored in inventory and pulled when needed could instead be printed on demand directly at repair and overhaul sites as 3-D printing advances.

The Air Force’s oldest planes, such as the venerable B-52 Stratofortress, often need parts that haven’t been manufactured for decades. Using 3-D laser mapping and other techniques, existing parts can be reverse engineered, and even improved, at air maintenance depots.

“The speed of it and the flexibility of it will very much improve our industrial base, where we’re repairing aircraft that are getting older and older,” Olivero said. “We have more and more instances of parts that we can’t get. All of this will help us be a better logistics center.”

Engineers designing new or improved parts could also get their final products out more rapidly. Traditional lathe machining, a subtractive process that carves parts out of blocks of material, can take months of machining time if a complex part needs multiple prototypes before it’s perfected, Olivero said.

“With additive manufacturing, that part may take a couple of hours to print and you can actually go through five or six iterations in days,” Olivero said. “Even if your final part is going to be machined, you can print it in plastic five times to make sure it’s got the correct geometries, the right tolerances, the correct interfaces, and then machine the final one.”

Additive manufacturing also has disadvantages in some cases, Olivero said. Some jet engine components must withstand extremely high temperatures and physical stresses. Parts milled traditionally from a block of forged titanium, for example, tend to have better molecular properties for that job than an identical 3-D-printed titanium part.

“For metals in particular, the additive manufactured properties are typically somewhat lower, so what you gain in speed and flexibility, you lose some mechanical properties,” Olivero said. “You can get good characteristics compared to 10 or 20 years ago, but it’s not as good yet.”

The scope of the strategic plan, scheduled to be completed in the coming months, is broad and will cover questions such as how to build engineers’ expertise with 3-D printing and what to do with troves of 3-D computer models that will be created.

“We know how to manage 2-D models,” Olivero said. “We have files of paper drawings. We have technical orders with drawings in them. Now we have to figure out how to store, classify, maintain and configure all of those 3-D models.

“It’s a completely different paradigm,” Olivero said. “There are new challenges, new processes and new capabilities, and we need to work out how to make all that work together for our benefit.”

According to Jamie Gilbert, the OC-ALC industrial process authority, “The biggest challenge is going to be changing the mentality of our engineering and technician workforce because right now most of the people in the complex aren’t used to additive manufacturing and working with 3-D models to manufacture parts and to design repairs.

“Even many of our young engineers who were just out of college four or five years ago, it’s mostly new for them,” Gilbert continued. “We’re going to have to learn how to incorporate it and insert it into our manufacturing machine.”

-ends-

Through the program, the companies will identify and explore cooperation projects to leverage each other’s advanced manufacturing expertise and strong commercial capabilities focused on serving the fast-growing needs of aerospace, defense, energy, automotive and maritime customers.

“We’re thrilled to deepen our relationship with Alcoa through this program, which is focused on advancing the global reach of our game-changing, 3D-printing Direct Metal Deposition technology,” said NTi President & Chief Executive Officer Warren M. Boley, Jr. “Through this cooperation program, we expect to build on our innovative technology capabilities by leveraging Alcoa’s in-depth understanding of lightweight metal components, increase our offerings for aerospace and other end markets, and support our goal of delivering near-net-shape titanium components finished with minimal machining.”

“Through this joint cooperation program, we will bring together Alcoa’s unmatched metallurgical know-how and deep aerospace industry relationships with Norsk Titanium’s 3D-printing technologies, to ultimately accelerate the introduction of advanced manufactured aerospace solutions,” said Eric Roegner, President of Alcoa Titanium and Engineered Products. “This program will further support our efforts to push beyond the limits of today’s additive manufacturing and meet fast-growing demand for 3D-printed aerospace parts.”

In July 2015, RTI International Metals, now Alcoa Titanium and Engineered Products, became a strategic investor in and minority owner of Norsk Titanium. The combination of NTi’s innovative technology with Alcoa’s vertically integrated titanium global supply has significant applications in the titanium closed-die forging market.

Today NTi is producing aerospace-grade titanium components with its fourth generation equipment. Based upon extensive material testing, Norsk Titanium expects to formally conclude the multi-year aviation certification process in the first quarter of 2016 and will begin producing titanium components for customer part qualification in 2016 and commercially producing titanium components for its customers by the second half of 2016.

Norsk Titanium AS (NTi) is a global leader in manufacturing performance critical titanium components for aerospace and industrial applications. The company has revolutionized the industry with its patented Direct Metal Deposition (DMD) technology that transforms titanium wire into complex components at better than half the time, cost, and waste levels of legacy processes. www.norsktitanium.no

A global leader in lightweight metals technology, engineering and manufacturing, Alcoa innovates multi-material solutions that advance our world. Our more than 60,000 people in 30 countries deliver value-add products made of titanium, nickel and aluminum, and produce best-in-class bauxite, alumina and primary aluminum products.